What is Vehicle Electronics PCB?

Let us begin by explaining the meaning of a PCB.

Printed Circuit Boards is a non-conductive board with all the electronic and electrical components. The electrical components connect to the board through a physical support aid.

An automotive printed circuit board is a complex circuit system that controls most of the electronic operations in a car.

Printed Circuit Board Assembly is a crucial component of vehicle electronics. It serves as the foundation for electronic circuits that control various aspects of the vehicle’s operation. Here are some key things to know about PCBA for vehicle electronics:

As a leading automotive PCB manufacturer of 15years’experience with IATF16949 compliant, we support PCB and PCB assembly prototyping to mass production for all your automotive PCB projects, by providing standard rigid PCBs,flexible circuit board and rigid-flex solutions to automotive manufacturers and their suppliers.

When designing PCBAs for vehicle electronics, there are several factors to consider, including:

Size and shape: The PCBA should be designed to fit within the available space in the vehicle and meet any dimensional constraints.

Component placement and routing: The placement of components on the PCBA and the routing of traces should be optimized for efficient operation and to minimize electrical noise.

Electrical and thermal requirements: The PCBA should be designed to meet the specific electrical and thermal requirements of the application.

Testing and validation: The PCBA design should allow for easy testing and validation of the board’s functionality.

Printed Circuit Board Assembly is an essential component of vehicle electronics that provide a stable platform for electronic components to interact with each other. There are different types of PCBAs used in vehicle electronics, and their design must consider various factors such as size, component placement, and electrical/thermal requirements. As technology continues to evolve, we can expect to see even more sophisticated PCBAs in future vehicles.

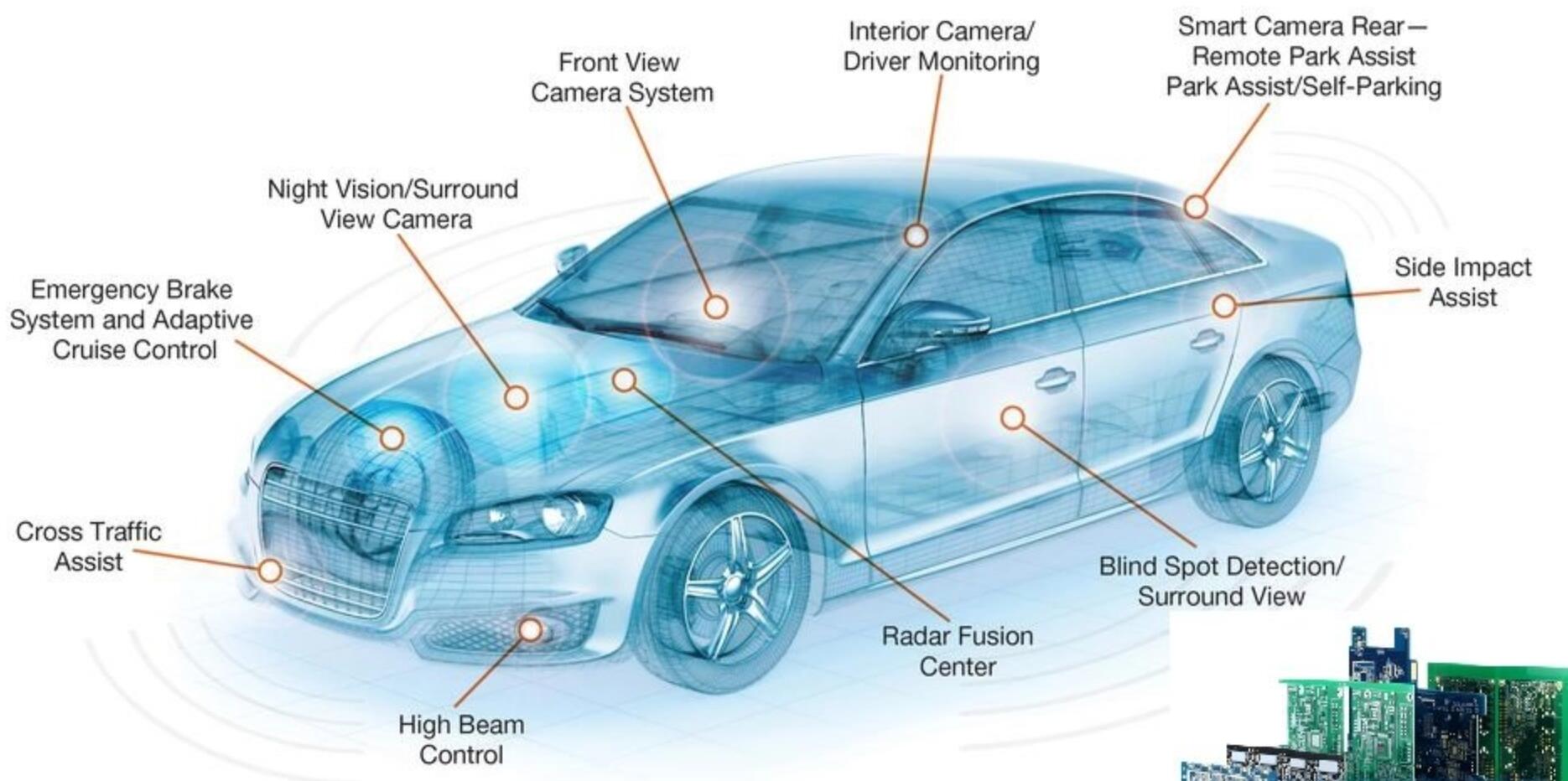

What Applications of the Automotive PCB

Different applications of vehicles are using in automotive PCBs. It can be stated that when it comes to applications, PCBs could be considered as the backbone of the electrical system.

The belows is the list of the main applications of automotive PCBs.

1.GPS kit&ECU modules.

2.Displays (Digital)&Sensors of transmission.

3.Radar system&Audio and stereo components.

4.AC/DC converters&Engine controls.

5.Engine timing system&LED system.

6.Occupant detectors&Power distribution board. manufacturing.

Quality Assurance Requirement

From an international perspective, the demand for quality products from manufacturers and distributors depend on ISO9001 regulations.

To be more specific, the quality administration system that govern the automotive industry id the ISO90001/TS16949.

It integrates special requirements and focuses on defect prevention, waste reduction and quality fluctuation in the automotive industry chain of supply.

As an automotive manufacturer, you have to obtain the ISO/TS16949 before genuinely entering the market.

To define a product under class 3, You must build it under the total IPC criteria. IPC class III standard dictates quality standards for:

Selection of laminates

Plating thickness

Manufacturing processes

Arrangement of facilities such as components on the PCB

Criteria of Inspection

Material qualifications

Automotive PCB Prototyping

You will need to have an automotive printed circuit board prototype before having the actual automotive PCB.

The prototype will guide you in making a good and complete automotive printed circuit board.

It will also assist you to know whether the automotive PCB design you need will work.

PCB for Automotive Industry Assembly

With the PCB prototype in hand, you are free to move on to the assembly process.

Before you proceed, you have to ensure that the PCB prototype is working perfectly.

Let’s have a look at some of the assembly processes you need to know.

Hitechpcba automotive PCB assembly advantage:

At present, driven by advanced technologies such as artificial intelligence, 5G communication, and vehicle networking, the intelligent vehicle has become another outlet after electric vehicle. With regard to PCB Assembly for automobiles, the purchase and production of PCB boards and components are also very strict. Hitechpcba has very rich experience in PCBA for automobiles, such as Harley-Davidson, Denso, and other automobile factories are our customers.

Although the production of automotive PCBA circuit boards is mature, it still requires a high level of management, posing challenges to the reliability of component and PCB patch assembly. Hitechpcba focuses on PCBA board quality manufacturing and becomes your preferred supplier. At the same time, we have extended our certification to the successful IATF 16949 automotive certification and has a great advantage in the manufacture of automotive electronic PCBA.

IATF 16949 describes the quality management system requirements for the design/development, production, installation, and service of automotive-related products. The standard requires that there must be a site, which is the production line where the value-added manufacturing process takes place. By manufacturing, all processes for the manufacture or assembly of the following items, including parts or materials, heat-treated parts, painted, electroplated, or other final processing services, as well as other customer-specified products.

In other words, IATF 16949:2016 applies to the organization of automotive manufacturing, automotive production and repair parts manufacturing, specifically automotive manufacturers, production of automotive-related materials, automotive assembly parts or heat treatment, welding, Organization of plating, painting or related services. IATF 16949:2016 lists quality system regulations for the design/development, production, installation, and service of automotive-related products.

Automotive Electronics Trends in 2023 and What to Expect in the Future

CES 2022 brought us a host of futuristic gadgets for vehicles and interesting concept vehicles, and the upcoming CES 2023 show is not likely to disappoint. The electronics in these vehicles are reflective of broader automotive electronics trends that can’t be ignored by carmakers, OEMs, aftermarket electronics designers, and consumers. PCBs are the backbone of automotive electronics, and the proportion of electronics costs currently occupies ~40% of the cost of a new car. This is expected to reach 50% by 2030, just at the point where new consumer automobiles are projected to be partially or fully autonomous. If you were to look under the hood of a 1950’s Chevy, it would be hard to imagine that the automotive industry has come this far.

It’s not just the number of electronic components that is expected to continue increasing, it’s also the complexity of these systems, both in terms of hardware and embedded software. Beneath these statistics are several automotive electronics trends that will drive component needs for OEMs and aftermarket designers. Let’s look at how these trends are influencing the landscape in electronics systems for new and future automobiles.

Top Automotive Electronics Trends

The most prominent trend everyone is familiar with is the current automotive chip shortage, which has unfortunately spilled over into just about every other area of the electronics industry. Automotive electronics span multiple application areas, ranging from power to sensing and wireless communications.

Power Management for Electric Vehicles

As the infrastructure in economically advanced countries changes, and as newer battery systems are developed, we can continue to expect electric vehicles with longer range and faster charging times. This all relies on more advanced power management systems, which rely on a range of fundamental components. These components are not necessarily highly integrated as SoCs simply because they need to handle so much power, but high power systems may still need to operate with discrete components on dedicated modules.

Some of the major power systems appearing in electric vehicles include:

Wireless BMS for managing charge distribution in EV battery packs, as well as monitoring batteries and communicating data back to control units.

Emergence of V2G technologies and bidirectional charging in electric vehicles at charging stations.

Use of more advanced semiconductors with high operating temperature and high thermal conductivity for power MOSFETs.

Some typical components that will need to be used in these power management systems include a range of components for sense and control loops, such as current sense amplifiers. As EVs operate with battery packs at high voltage, components for ESD protection are also essential to protect circuits. Integrated power management ICs with multiple regulators (see the MC33PF8200A0ES from NXP below) are being used to control these systems, as well as automotive-qualified processors and a suite of ASICs.

Regarding power FETs that need to run at high power for charging/discharging management, SiC and GaN-SiC are ideal material platforms for these switching components. In particular, SiC is a wide indirect bandgap semiconductor (3.3 eV bandgap) that provides low losses during power conversion at relatively low switching frequency. It also has high thermal conductivity compared to Si, making it an ideal material for high power conversion tasks in electric vehicles. While these components were originally developed to target RF power applications, such as in newer mobile infrastructure, they are just as useful in power applications for electric vehicles. In fact, the first automotive-qualified GaN FET with an integrated driver was announced last year, and other companies have followed suit with their own components.

In-vehicle and Smart Infrastructure Networking

New cars are processing more data than ever before, and the amount of data they use will only increase. In-vehicle networking in consumer automobiles is currently below 1 Gbps over Ethernet, but Gigabit in-vehicle Ethernet and wirelessly connected devices within the vehicle will change the way data is collected and handled by vehicles, as well as the driver experience. In-vehicle networking and smart infrastructure networking are both huge opportunities for new automobiles and are seen as a new growth market by the automotive industry. In-vehicle networking alone is projected to become a $1.5 billion market by 2026, which will be facilitated by a host of integrated processors and SoCs.

Sensors for Smart ADAS

Some experts say it will be approximately a decade before consumers can buy a self-driving car. There are many reasons for this, which largely revolve around the development of a suite of advanced algorithms for governing control and decision-making. However, there are other challenges that need to be solved at the hardware level. Then there are the regulatory challenges and infrastructure required to support autonomous vehicles. These challenges exist both within the vehicle, outside the vehicle, and in relation to other cars being driven by humans.

The current sensor landscape for ADAS involves some combination of ultrasonics, radar, and cameras, all of which need to connect to an ECU. Lidar may also become common in ADAS sensor networks as it enables depth mapping that is not possible with camera images. Lidar is interesting as it is not limited to use in automobiles, with the technology being useful for sensing and imaging in smart cities generally. Even though lidar was not the main focus of conversation in years past, companies are still pushing it as part of an advanced solution for smart ADAS systems as it provides higher resolution imaging and mapping to support radar and vision systems in new vehicles.

Components required for ADAS sensors span beyond the sensors themselves and include the following:

Radar transceivers and SoCs (24 GHz and 77 GHz)

Lidar system components, including pulsed laser diodes

Multichannel ADCs and embedded processors for sensor fusion

Components for custom cameras, including CCD/CMOS sensor modules

Some sensors and their supporting components may need to communicate with each other over standard digital interfaces (I2C, SPI, CANBus, etc.), while analog sensors may use a standard 0/5 V/4-20 mA interface (e.g., environmental sensors).

Processing Power

Current cars contain somewhere in excess of 100 ECUs, and the number is only expected to increase. As the amount of data gathered and processed in automobiles increases, ECUs and other modules in the system will require more processing power in the form of MCUs and automotive-grade FPGAs. The exact size, speed, and location of these components is still an open question. Given the trend in integration seen in the specialty IC market, I would expect many manufacturers to start offering and/or marketing automotive-specific SoCs that integrate an MCU.

The range of wireless services, power management systems, and processing power required for new vehicles should reveal the complicated electronics landscape in new vehicles. It’s impossible to keep up with all automotive electronics trends, but designers that need to select components for these systems can get a complete view of the supply chain with a powerful electronics search engine. Chipmakers are likely to respond with specialty SoCs, similar to those for IoT and mobile products, and you can find these and other specialized components for new vehicles with the right search engine.

How To Obtain a Quote

You can easily place small batch orders underground and obtain PCB assembly quotes. Just forward your requirements and contact information to sales@hitechpcb.com . We will reply as soon as possible.

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese