Cable & Harness Assembly

What is Wire Harness and Cable Assembly?

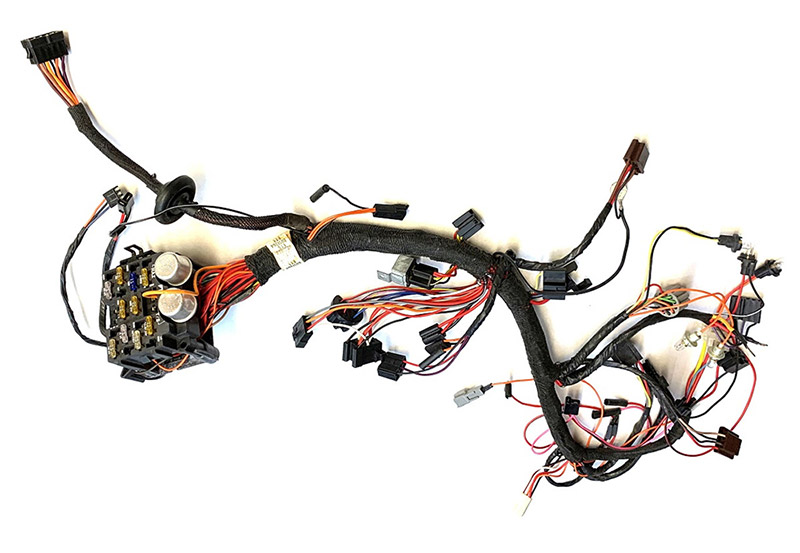

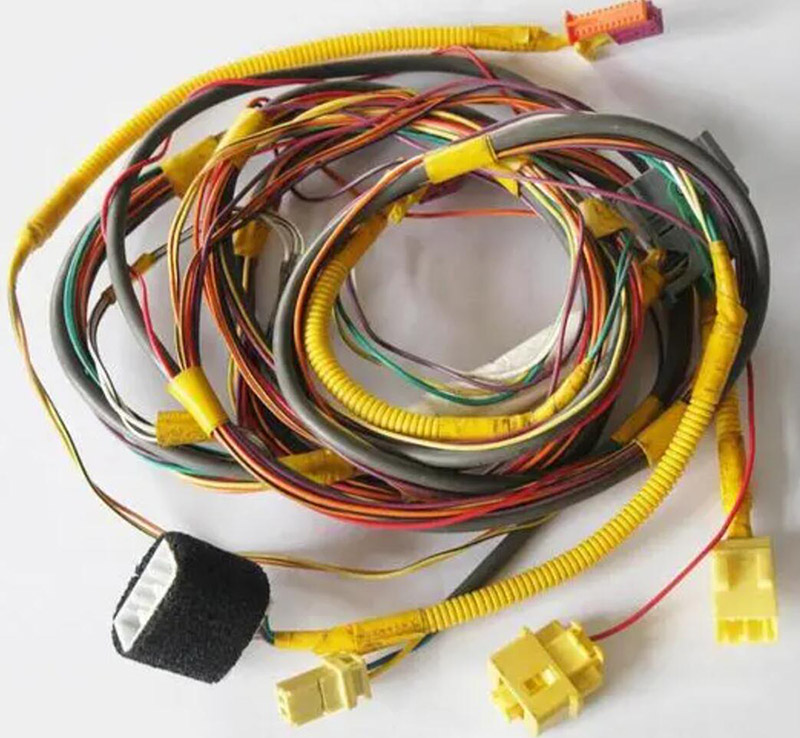

Wire Harness is also known as cable and harness assembly, wire assembly or wiring loom applicable to the interior of electronic, computer, automotive, industrial and consumer products. The wire harness simplifies the connection to larger components by integrating the wiring into a single unit for “drop-in” installation. As one of the leading wire harness and cable assembly manufacturers in

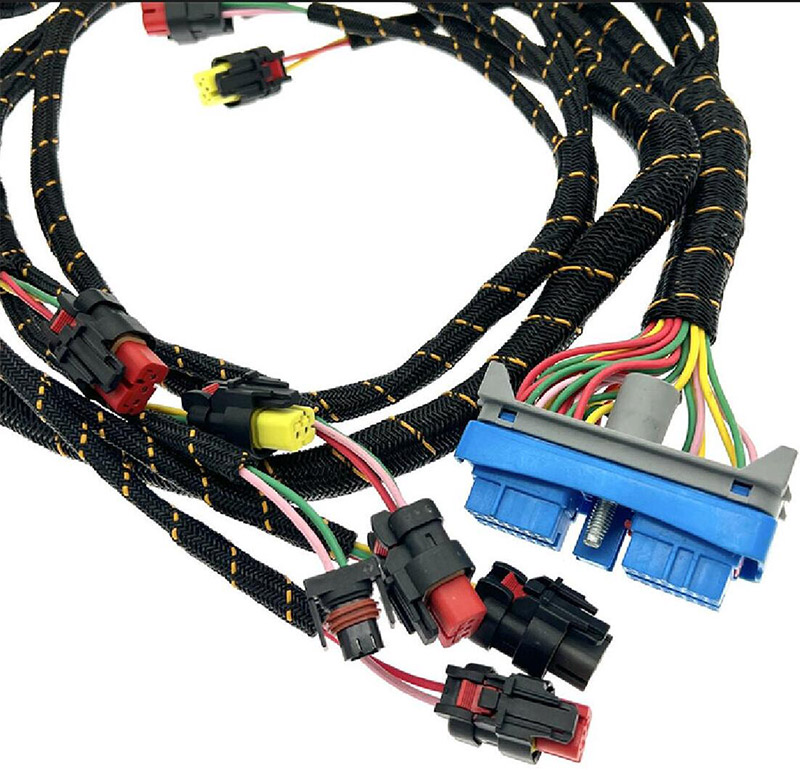

Cable Assembly, also known as a wire harness, wiring harness, a cable and harness electronics, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power. Cable Assemblies are often confused with Wire Harnesses, however, the two are quite different. The main difference is that cable assemblies and harnesses normally have only two ends, whereas a wire harness contains multiple breakouts (ends) that run in many different directions with multiple terminations on each breakout.

Quick-Turn Cable Assemblies & Wire Harness Assemblies

In a hurry? We can provide quick-turn cable assemblies and wire harness Assemblies for your projects.

Hitechpcba has multiple cable assembly houses worldwide to meet your local needs. For low-volume cable assemblies, wire harnesses, quick-turnaround cable assemblies & wire harnesses, our cable assembly houses in Shenzhen, we can provide fast and efficient cable and wire harness assembly manufacturing services. For high-volume cables & wire harness assemblies, OEM cables, and industrial cables, our owned cable assembly house in

Contact any of our local support operations for immediate assistance. We have dedicated quick-turn manufacturing procedures specifically for rush orders in addition to prototypes and volume manufacturing requirements. We are members of the Wiring Harness Manufacturer's Association and BICSI. We can meet the industrial standard and your requirements.

For OEMs requiring simple cable assemblies through to complex wiring harnesses, you can be confident at Hitechpcba will provide a high-quality service.

We can manufacture a broad range of cable assemblies, from prototype to volume production. We also co-ordinate the entire supply chain and provide certifiable traceability.

Hitech Circuits has a breadth of experience gained producing simple point-to-point cables and straightforward looms, to multi-component assemblies and complex looms. We can process cable from 36AWG to 6AWG for use in demanding environments, including medical, surgical or high-end audio.

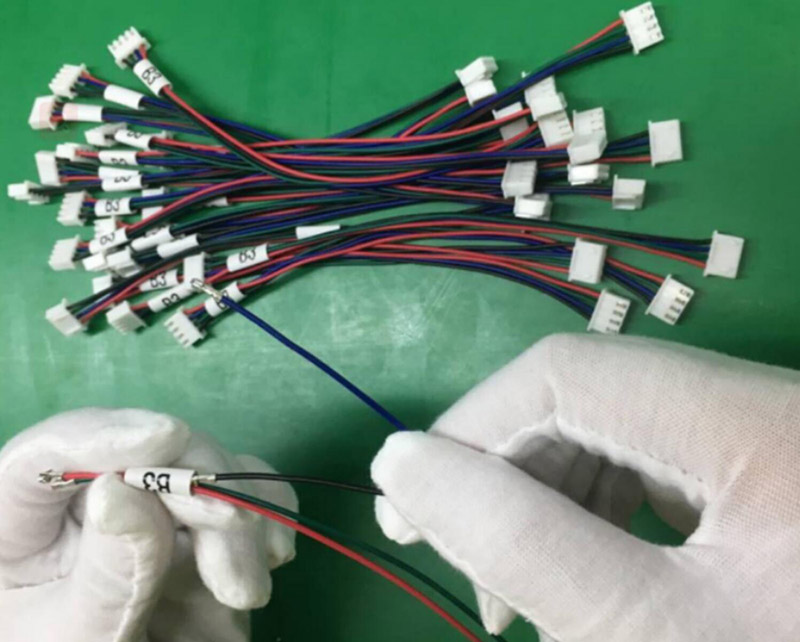

We have highly trained engineering and assembly teams to assist with design and carry out the assembly and support for all your cable and loom requirements.

Our dedicated build cells feature Schleuniger and Seno automatic cable cut and strip machines and are designed for low volume complex harnesses through to medium volume cable assemblies. We can accommodate various cable types, including coaxial - and have several automatic crimp machines for a host of manufacturers, such as JST, Harting and Amp. Cable assemblies are continuity tested, usually with Banair or Cirris automated equipment, before shipment or use in higher level assemblies.

Whether your requirement is for a single single-ended wire or a full harness complete with connectors, switches and fuses, you can be confident that we will provide a high-quality service, right first time.

Why Choose Hitechpcba for your Cable Assembly Manufacturing Needs?

Hitech Circuits manufactures the highest quality custom cable assemblies’ available using state-of-the-art equipment. We provide exceptional value-added services, from custom wire marking to wire cutting services, to give our customers the best value and highest dollar-for-dollar return on their investment.

Hitechpcba provides the following advantages:

Decades of knowledge and experience

Products designed and built at the facility in

Consistent communication throughout the entire project

Quality control standards and certifications

Competitive pricing

Excellent ROI

Utilization of only the highest quality materials

At Hitech Circuits, we have more than 15 years of experience providing the highest quality custom cable and harness assemblies to high-tech customers worldwide. We use various processes such as manufacturing, ultrasonic welding, and injection molding to provide excellent products and services, from simple to complex cable and harness assemblies, from prototypes to turnkey services, we can always meet the various needs of our customers. We have an excellent team to assist you in real-time and effective communication, speeding up the entire assembly process and time to market.

With our professional engineering team , we offer quick turnaround times and exceed our customers' expectations at every stage, from product design to manufacturing and delivery.

At our company, we prioritize delivering high-quality cables and custom cable assembly services to our customers. We achieve this by investing in the latest equipment and technologies in the industry. Our focus on innovation allows us to provide our customers with competitive prices without sacrificing the quality of our products.

Whether you need a simple or complex order, we are capable of delivering on time and within budget. Additionally, we offer the flexibility of using either original or equivalent parts, which can save both time and money for our customers. Partner with Hitech Circuits today and let us help you win more business by providing you with superior quality, competitive pricing, and reliable delivery times.

Innovative Cable Assembly Solutions

Hitechpcba is the industry’s foremost cable assembly manufacture. Our extensive inventory enables us to supply our customers with complete turnkey solutions. If it’s a custom cable, that’s not attainable we have partnered with key custom cable manufacturers who don’t have high MOQ’s, and are competitively prices.

We can provide:

1. Cable assembly – Whether you require your cable assemblies to meet specific temperature, moisture, size, or color requirements, our custom options have you covered.

2. Wire harness assembly – Our wire harness assemblies for industrial OEMs and manufacturers are entirely custom processed, delivering a finished product that meets project specs.

3. Wire processing – Utilizing state-of-the-art robotic equipment, Hitechpcba offers a variety of value-added wire processing services for manufacturers and OEMs, including wire stripping, wire cutting, and more.

4. Wire terminations – We carry most terminal manufacturer’s, and are tooled for automatic crimping.

Wire identification – Whether it’s sequential numbering, date codes, serial numbers, or custom labeling, we can print nearly anything on your custom wire harness or cable assemblies.

Cable Assembly Options for All Applications

We provide innovative, long-lasting cable assemblies for customers across the country and worldwide in all industries. Our products offer superior performance and are electrically tested for the most demanding industries, including:

Electronic Cable Assemblies

Medical Cable Assemblies

Automotive Wiring Solutions

Lighting Wire Harnesses

Solar Panel Wiring

Cable Assemblies Manufacturing Capabilities

Hitechpcba can create custom Cable Assemblies in any configuration you require. There are essentially no limits to our manufacturing capabilities. We build your Cable Assembly based on your completed designs, or our in-house application engineering team can work with you to turn your designs into fully functional Cable Assembly that meet your exact requirements. One of our capabilities is wire identification before the jacket is extruded over all the individual wires, we can identify those individual leads to help simplify manufacturing at your facility and installers in the field. We can also add date codes and serial numbers for traceability.

Your custom wire harness designs can include:

Unlimited selection of wire, gauge, insulation style, and color‘s

Any number of wires

Any manufacture Terminal, & Connector

Molex

Furukawa

Sumitomo

Delphi

Deutsch

We also manufacture Custom Connectors

Every custom Cable Assemblies that we produce is electrically tested to ensure proper performance, we can also add a label that includes part number, date of manufacture for tractability.

Custom Cable Assembly Design Resources

Hitechpcba’s application engineers are here to answer any questions you may have and help you conquer any design challenges you may be facing. We can work with your design Team and recommend adjustments if needed. We can create prototypes and first articles, allowing you to test your designs for form, fit, and function.

Because we offer complete turnkey solutions, your staff is free to concentrate on other vital projects while we handle the entire Cable Assembly manufacturing process. Once your final design is approved, and your purchase order has been received, we will submit a 1st article to review. After the approval process, we review deliver dates with your staff, and production begins.

Quality

All of our Cable assemblies are electrically tested, and are built to IPC/WHMA-A-620 standards, we are ISO compliant see our quality standards. We can supply you with our current Quality manual if you would like a copy.

Contact Hitechpcb for Turnkey Custom Cable Assembly and Wire Harness Solutions

If you have any questions, please contact us, we look forward to hearing from you. From the simple to the complex, we can manufacture your custom wire harness and Cable Assembly for any application. To learn more about the custom solutions Hitechpcb can provide to your business, contact us or call us at 0086-755-29630063 for a direct pricing quote on your next wire harness or wire harness assembly project.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

3F, B5 Dong, Zhimeihuizhi, FuYong, Bao’an Dist. Shenzhen, GuangDong, China 518103

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese