What is New Energy PCBA?

New energy PCBA is manufactured and designed to optimize power usage and energy efficiency, and sustainable practices are promoted when innovative techniques are used.

These PCBAs are most commonly used in energy storage equipment, battery management systems, outdoor power equipment, electric vehicles, and smart grids. These PCBAs create efficient and effective communication between the components of a device and, at the same time, manage and monitor energy consumption.

The new energy PCBA creates integration between components, including modules that store energy, like batteries, sensors, and control systems. This allows them to coordinate, ensuring that energy flow is regulated and power is optimized.

When it comes to meeting critical and reliable energy requirements, Hitechpcba is a leading provider of energy PCB manufacturing services. With expertise spanning various sectors such as high-voltage power, renewable energy systems, industrial production, transportation, and avionics, Hitechpcba ensures that your energy application PCBAs are of the highest quality and reliability. Whether you need fast turnarounds, efficient prototyping, or on-demand PCBA production, partnering with Hitechpcba guarantees exceptional results.

New Energy PCBA Introduction

As time passes on, new technology is highly inclined towards developing solutions that help in manufacturing such equipment and solutions that are energy efficient.

The concept of sustainability is on the rise. The demand for catering to the different equipment and developing New energy PCBAs are meeting these demands by protecting the environment and offering sustainable solutions.

New energy PCBA is observed to be widely used in multiple industries, among which the automobile sector is a common one. If you are looking forward to knowing more about this PCBA, like the different types of it, its applications, and how they benefit industries and the environment, you must go through this guide below.

Applications of PCBA in Energy

PCBAs play a vital role at every stage of the energy supply chain. They are integral components of systems operating in generating stations, energy storage locations, transmission and distribution lines, and consumption facilities. These electronic devices include sensors, controllers, inverters, voltage regulators, digital relays, communications, and safety devices. Energy PCBAs are designed to monitor, control, regulate, and drive conventional power system elements, as well as support advanced digitization implementations like IoT. Moreover, they must withstand extreme conditions such as high temperature, thermal cycling, pressure cycling, vibrations, and shock for prolonged periods.

Objectives of New Energy PCBA

New energy PCBA has been manufactured based on certain objectives, which are discussed below:

How is New Energy PCBA Used in Different Ways?

The types of New energy PCBA depend on the requirement of the application, and some of the common types may include the following, where each type fulfills a different purpose.

PCBA for Renewable Energy

This PCBA is suitable for using renewable energy systems, like solar or wind power systems. These PCBAs comprise such components that help with the process of harvesting energy and utilizing it with efficiency.

PCBA for Energy Storage

As the name suggests, New energy PCBA can also be used for storing energy, and this is integrated with the components focused on storing energy, like batteries. They help in the appropriate utilization and energy storage optimization of the devices.

Electric Vehicle PCBA

New energy PCBA plays a significant role in electric vehicles because these vehicles work through electronic systems. They need an efficient system in place that helps coordination between its motor control and battery management so that they can utilize the electricity in the best possible way.

Power Optimization

The main theme behind designing and manufacturing New energy PCBA is maximizing energy efficiency, which is one of the prime requirements for devices that use high power. Hence, by incorporating these PCBAs, energy losses are reduced, and devices' efficiency is improved.

Sustainability to the Environment

New energy PCBAs promote the usage of renewable energy resources, and hence this way, the carbon emissions are reduced. The requirement of being dependent on eco-friendly technological innovations have led to the development of these PCBAs, and they are doing this job very well.

Conservation of Resources

Using devices that comprise the New energy PCBAs, non-renewable resources like fossil fuels can be reserved for a future generation because utilizing less of the resources and optimizing energy could be conserved for the better.

Improved Power Conversion

New energy PCBA has been designed in a way that it helps with efficient conversion of power in different forms, for instance, from AC to DC. This aspect of these PCBAs leads to reduced wastage of energy, and hence the performance of the systems is improved.

Specific Applications for Energy PCBAs:

Generation: Energy PCBAs are essential in oil and gas extraction, energy harvesting from renewables, and energy conversion. They enable sensory control and data acquisition (SCADA) operations, incorporating devices such as DC-DC converters, inverters, power supplies, and DAQ boards.

Storage: PCBAs play a critical role in battery storage for portable or standalone electronic systems, including electric vehicles (EVs) and autonomous vehicles (AVs). They are also instrumental in managing intermittent renewable sources such as solar and wind farms, with applications in controllers, conversion, inversion, thermal regulation, battery management, and power distribution.

Transformation: Energy PCBAs are vital in the transformation process within the energy grid system. They are used in transformers that increase voltage for long-range transmission and decrease voltage for localized distribution. These PCBAs ensure efficient conversion, distribution, regulation, and safety, not only in the grid system but also in factories and production facilities.

Transmission and Distribution: PCBAs aid in the transportation of energy across long distances, from drilling operations to consumers. They regulate parameters and facilitate fault detection and alleviation, ensuring the operational requirements of energy transmission and distribution are met.

Consumption: Energy systems power various establishments, from businesses and factories to commercial and residential structures. With the growing adoption of EVs, charging stations have become integral to power system planning. Energy PCBAs help ensure the safe and reliable supply of energy to these charging stations.

Significance of New Energy PCBA in the Automobile Industry

New energy PCBA has been quite popular in the automobile industry. There are many reasons which make this automotive PCBA suitable for vehicles, and some of these are as follows:

Temperature Management

New energy PCBAs can withstand high temperatures and allow them to dissipate heat; hence, when used in vehicles for their energy efficiency, they can last longer and may resist the heat released from the vehicles.

Suitable for Every Environmental Condition

The lifespan of New energy PCBA is very long because it is manufactured with high-quality material to make it suitable for being used in harsh working conditions and subjected to all kinds of environments.

Vehicles need this feature of PCBA so that when subjected to different climatic conditions or harsh conditions, the PCBA may function efficiently.

Resistant against Dirt

Vehicles are usually subjected to attracting dirt, leading to malfunction within them. However, the New energy PCBA is manufactured in a way that resists dirt; hence, the vehicle's functioning and power efficiency are not compromised.

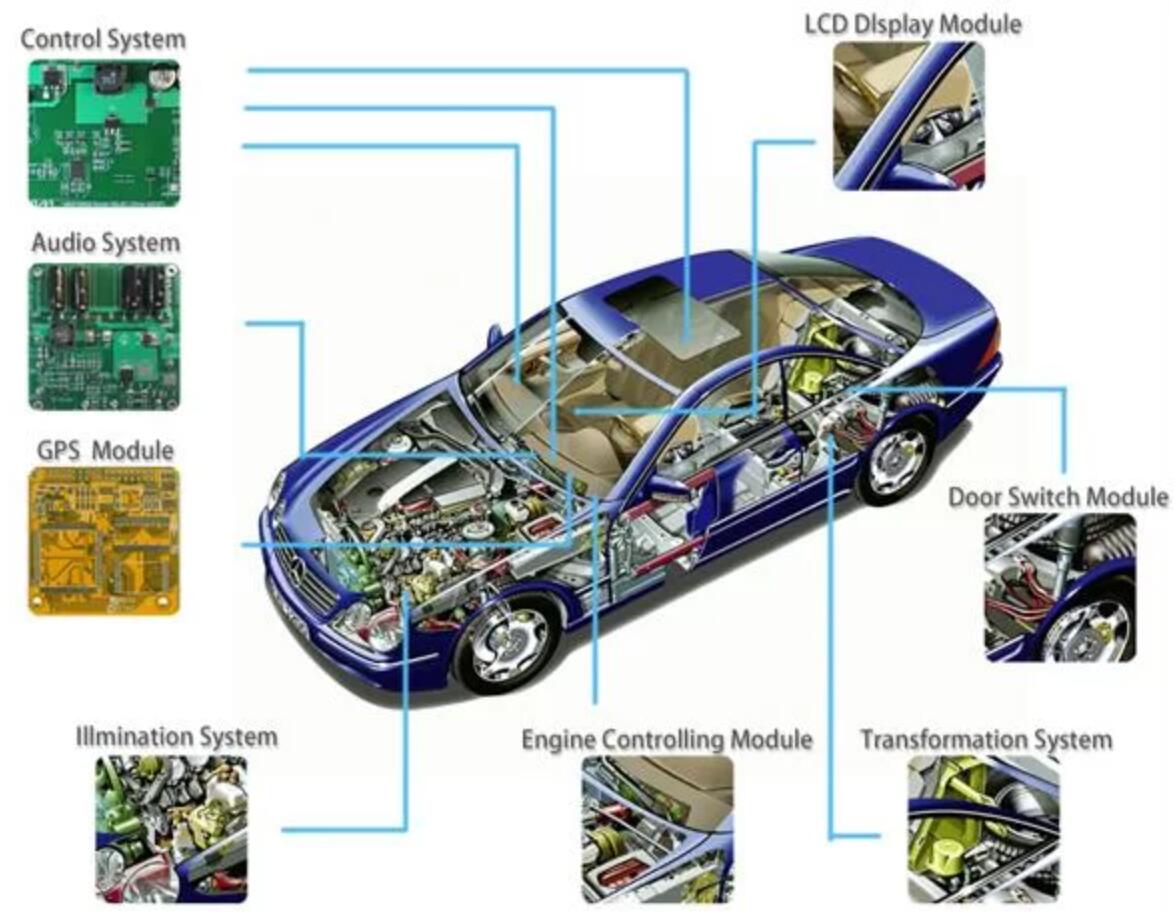

Application of New Energy PCBA in the Automobile Sector

In the automobile sector, the use of New energy PCBA is quite prevalent and is present in multiple aspects, and some of these applications are provided below:

Battery Management System

The battery management system of the vehicles comprises a battery pack that charges and discharges, and this PCBA ensures that the limits of the battery pack are operated within the safety range.

Power Electronics

Power electronics like DC-DC converters, inverters, and motor controllers need to regulate the voltage in the electrical system of automobiles. This PCBA helps regulate the voltage to ensure accurate power flow.

Vehicle Control Unit

Vehicle control units present within the cars comprise many systems, including brake, motor, and suspension. To allow the communication between these systems to be coordinated, the PCBA may be of great help.

Charging System of Vehicle

A vehicle's battery pack consists of charging systems, and here, this PCBA helps control and monitor the charging process, ensuring that the battery is appropriately charged.

New Energy PCB and PCBA for Automobile

In recent years, new energy vehicles and driverless vehicles have become popular, and the traditional automobile industry is developing in the direction of intelligence and electrification. With the promotion of new energy vehicles, as the infrastructure of electronic products, the importance of PCB manufacturing in the automotive supply chain is also increasing day by day.

The development of two-wheel drive in the electrification and intelligence of automobiles has driven the increase of the PCBA New Energy Automobile. The demand for high frequency and high speed has caused structural changes in the PCBA New Energy Automobile market. The growth space of high frequency and high speed PCB is relatively larger, the technical barriers are higher, and the market concentration is greater. On the one hand, compared with the traditional fuel engine drive system, the electronicization of the car increases the PCB requirements of the electronic control system. On the other hand, the core of the new energy vehicle is the battery, motor and electronic control. Compared with the traditional car, its electronic ratio is A substantial increase. These two factors have increased the use of PCBA New Energy Automobile industry, and PCB Assembly New Energy Automobile will usher in greater development space with the growth of the market size of new energy vehicles.

As more and more electronic components are used in new energy vehicles, more and higher requirements are put forward for PCB products, so that high-reliability PCBs have more opportunities. Mainly high-speed and high-frequency PCB Circuit boards, High density PCB, FPC and other high-end PCB circuit boards facing the future.

PCBA New Energy Automobile as an important component material used in new energy vehicles, has also risen in demand. Hitech Circuits can develop and produce corresponding new energy vehicle circuit board PCBs according to customer needs, and professionally provide customers with high-quality high-end samples and design services.

Meeting the Challenges of Renewable Energy Electronics Design

Designing and manufacturing printed circuit boards (PCBs) for high-power applications in the renewable energy industry requires a high level of manufacturing sophistication. Hitechpcba understands the unique challenges involved in building PCBs that can withstand the demands of managing high-power loads. From selecting the right materials and components to ensuring signal integrity in high-noise environments, Hitechpcba offers precision PCBA manufacturing solutions tailored to the needs of energy applications.

Addressing Design Concerns:

PCB Materials: High-power PCBs require specific materials that can withstand the operating environment. Hitechpcba’s expertise includes a deep understanding of these materials and the ability to select the most suitable ones for your specific application.

High-Power Electronics Support: Selecting components that can perform reliably in high-power circuits is crucial. Hitechpcba’s experienced component engineers can guide you through the vast range of options, ensuring the right components are chosen for your design.

High-Power PCB Design Expertise: Designing circuitry for energy applications demands specialized skills and experience. Hitechpcba provides knowledgeable resources to answer your design questions and offer valuable insights throughout the design stage.

Power Distribution and Management: PCBs for high-power applications must effectively manage the distribution of power to multiple recipients. With Hitechpcba’s expertise in designing such boards, you can benefit from their experience in creating efficient power distribution systems.

Signal Integrity in High-Power and High-Noise Environments: Ensuring signal integrity in the presence of high-power loads and noise is critical. Hitechpcba’s skilled resources can help optimize your design to maintain signal integrity and minimize potential issues, saving you time and costs.

Custom Cables and Harnesses: High-power applications often require specialized cables and wiring harnesses. Hitechpcba, with its expertise in PCB and cable manufacturing, can assist in expediting the design and manufacturing process by providing tailored solutions for your high-power needs.

Hitechpcba specializes in meeting the requirements of various industries, including renewable energy and high-power applications. With their proprietary processes and manufacturing expertise, Hitechpcba ensures that every aspect of your job, from design to final quality assurance and testing, is meticulously controlled and documented.

Key Advantages of Choosing Hitech Circuits

Proprietary Processes: Hitechpcba’s finely-tuned manufacturing processes guarantee that your PCBs are built correctly, from start to finish, with strict control and documentation at every stage.

Manufacturing Expertise: Hitechpcba’s extensive experience enables them to adjust their processes to accommodate the unique requirements of high-power PCB designs. They can tailor assembly flows and ensure proper thermal connections for high-power components.

Component Engineering: Hitechpcba’s component engineers possess in-depth knowledge and industry connections, assisting you in identifying optimal components that meet the assembly process requirements of your design in terms of lifetime, price, and availability.

Design Optimization: Hitechpcba’s engineers have the necessary expertise to optimize your design for high-power applications, ensuring a high-quality assembly process and overall performance.

Factors to Consider When Choosing New energy PCBA

There are some factors that must be taken into consideration when it comes to choosing New energy PCBA, and these may include the following:

It is very important first to determine the power requirements that your system might have, and this includes voltage level, the capacity of current, and the power distribution requirement. The New energy PCBA that you are choosing should be capable of handling the power load you need.

The New energy PCBA you choose should emphasize reducing power conditions to minimize the loss of energy and ensure power management is up to the mark.

Depending on the applications you need a New energy PCBA for, you must choose it or have it designed to meet your application's specifications.

Ensure that the New energy PCBA you are choosing takes into account all kinds of protection measures, including temperature monitoring, protection against over current, etc.

The New energy PCBAs are designed to reduce the environmental impact and promote sustainability. Hence, look for the New energy PCBA that claims to be environmentally friendly so that you can also ensure using a sustainable mechanism within your systems.

Conclusion

New energy PCBA has a lot of benefits and features, and the way it assists multiple industries, especially the automobile industry, has led to a reduction in carbon emissions and managed power considerations in multiple devices efficiently.

If you are looking for one of the finest China New energy PCBA manufacturer, you can consider Hitech Circuits. It could be your one-stop solution to have a New energy PCBA designed and manufactured for your applications and fixed within your devices. We offer affordable and customized solutions for our clients, so get in touch with us today!

Hitechpcba‘s Energy PCBA Manufacturing Services:

Hitechpcba Automation understands the technological advancements driving the energy industry and the challenges faced by energy OEMs and ODMs. Whether you are developing devices for high-power systems, harsh environments, electrical grids, or renewables, Hitech Circuits offers advanced, software-driven PCB assembly services for your energy PCBA board development process.

FAQs:

Q1: What considerations are important when selecting PCB materials for high-power applications in renewable energy?

A: When choosing PCB materials for high-power applications, factors such as temperature resistance, electrical insulation properties, thermal conductivity, and mechanical strength are crucial. The selected materials should be able to withstand the specific operating environment and support the power requirements of the application.

Q2: How does Hitechpcba ensure signal integrity in high-power and high-noise environments?

A: Hitechpcba employs advanced design techniques and expertise to mitigate signal integrity issues in high-power and high-noise environments. This includes careful layout design, controlled impedance matching, noise isolation strategies, and shielding techniques to minimize electromagnetic interference (EMI) and maintain signal integrity.

Q3: Can Hitechpcba assist with designing custom cables and harnesses for high-power applications?

A: Yes, Hitechpcba has expertise in both PCB and cable manufacturing. They can work with you to design and manufacture custom cables and wiring harnesses that are specifically tailored to handle the extra loads and power requirements of high-power applications.

Q4: How does Hitechpcba ensure the reliability and quality of PCBAs for renewable energy electronics?

A: Hitechpcba has proprietary processes and stringent quality control measures in place to ensure the reliability and quality of PCBAs. These processes include thorough testing, documentation, and adherence to industry standards. Hitechpcba’s manufacturing expertise and experience in renewable energy applications further contribute to the reliability of the produced PCBAs.

Q5: What advantages does Hitechpcba offer for renewable energy PCBA manufacturing?

A: Hitechpcba offers several advantages, including:

Specialization in renewable energy and high-power applications, with a deep understanding of the specific requirements and challenges in this field.

Proprietary manufacturing processes that are fine-tuned to accommodate the needs of high-power PCB designs.

Experienced component engineers who can assist in selecting optimal components for lifetime, price, and availability.

Design optimization expertise to ensure high-quality assembly processes and overall performance.

Q6: Can Hitechpcba handle high-volume production of renewable energy PCBAs?

A: Yes, Hitechpcba has the capabilities to handle high-volume production of renewable energy PCBAs. Their advanced manufacturing processes, efficient assembly flows, and quality control measures enable them to meet the demands of high-volume production while maintaining reliability and quality standards.

Q7: Does Hitechpcba provide support throughout the entire PCBA manufacturing process?

A: Yes, Hitechpcba provides comprehensive support throughout the PCBA manufacturing process. From initial design consultation to final quality assurance and testing, our experts are available to assist with design optimization, component selection, manufacturing considerations, and any other concerns related to renewable energy PCBA manufacturing.

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese