China PCB Assembly manufacturer – Hitech Circuits, the PCBA supplier for Telecommunications & Networks, PCBA boards smt assembly and turnkey electronic contract manufacturing OEM EMS company,full system integration box build in china.

Hitech Circuits is a reliable contract electronic manufacturing source for the telecom industry. If you need custom PCB assemblies, box builds, or wire harnesses, you’ll receive competitive pricing, compared to other PCBA manufacturers, thanks to our relationships with top suppliers. If you need custom work, our experienced Telecom & Wireless electronics contract manufacturing services team can assemble devices to any specification or kit complete installations.

Application Areas for Telecom PCB Assembly

Communication products range from consumer communication products to industrial and aviation products. With the advent of 5G, communication products will be rapidly updated, especially mobile phone products. In the field of communication PCB Assembly; it is widely used in a wireless network, transmission network, data communication, fixed network broadband.

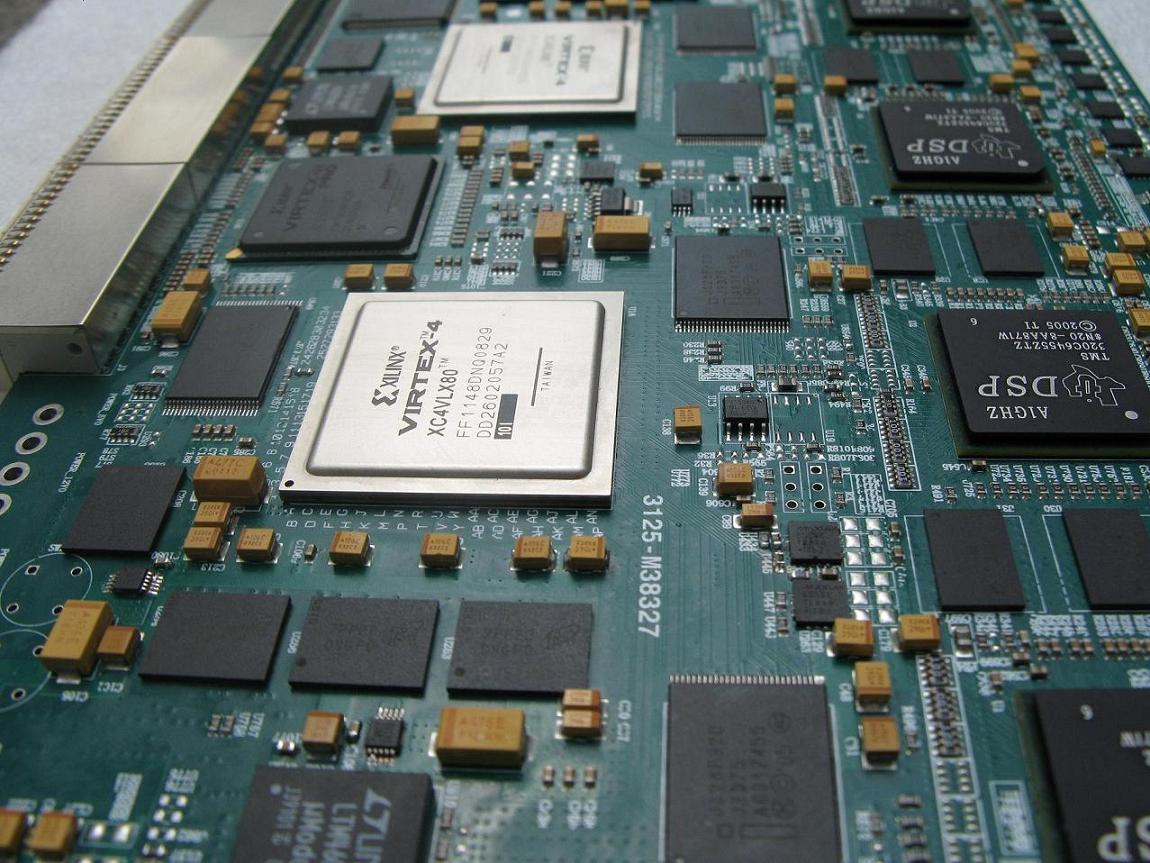

The related products include a backplane, high-speed multi-layer board, high-frequency PCB microwave board, a multi-functional metal substrate, etc. The communication equipment manufacturing industry provides communication equipment and software systems for basic communication operators and content (application information) service providers and provides various terminal application equipment for terminal customers. It plays an important role in the whole communication industry and is very important for communication transmission and application.

Which types of PCBs are utilized in the telecom PCB assembly sector?

Back-plane, high-speed multi-layer, and high-frequency microwave PCBs are used in base stations, OTN transmission, routers, switches, servers, OLTs, ONUs, and other telecom equipment. Telecom PCB assembly are high-speed and high-frequency. To meet capacity and speed requirements, the service/storage field used 33% 8-layer and above PCBs, while telecom PCB equipment used 42%, which is much higher than other subdivisions—besides high-speed PCBs, base station equipment uses a lot of high-frequency telecom PCBs to process antenna boards and power amplifier boards. Power supply, microwave communication, and other PCBs exist.

What are the challenges of telecom PCB assembly?

High dependability

Telecom pcb assembly equipment must be stable, reliable, and able to run continuously throughout the year. Equipment such as program-controlled switches and optical transceivers with a yearly failure time of less than a few minutes. With dual-system hot backup purposes, the host may seamlessly transition to the backup system when the host fails, and the switch has no effect on the equipment's operation or data loss.

Energy Conservation

The traditional manner of telecom pcb assembly network infrastructure building results in significant energy consumption and operating costs for the operator's communication network. Reduced energy consumption, the transformation of energy infrastructure, and assistance in achieving carbon neutrality targets are critical for operators in the 5G network implementation process, whether in terms of lowering operational costs or meeting the enterprise's social duties. Many of the world's top companies and conglomerates have announced carbon neutrality targets and begun low-carbon initiatives.

A Strenuous Application Environment

Telecom pcb assembly equipment is widely deployed, infrastructure is frequently exposed to the severe environment, and there is plenty of extremely difficult industrial situations. It is vital to ensure robustness in such applications. Because of the sheer size of communications infrastructure, maintenance must be maintained to a minimum in order for infrastructure investments to be cost-effective.

Communication PCB assembly importance:

Since the beginning, with the continuous development of industrial technology, relying on manual manufacturing and low precision, it has become increasingly unsuitable for the needs of modern industry. Up to now, the intellectualization and refinement keep pace with the development of the times. PCBA board is the most important part of electronic equipment, and its quality stability is very important for the normal function of terminal electronic equipment. With the development of electronic products in the direction of short, small, thin and light, the technical requirements for PCBA processing are more stringent.

The communication equipment manufacturing industry has a higher demand for PCBA. PCBA is the central nervous system of many intelligent products. Whether an intelligent product can play its due role in people’s life is closely related to PCBA. It can be said that the higher the quality of PCBA and the more stable its performance are, the greater the role of intelligent products can play.

Therefore, PCBA affects people’s intelligent life in the future. Communication equipment is now mainly developing towards miniaturization, speediness, and convenience. In addition, the market is becoming more and more saturated and the competitiveness is increasing. Therefore, there is an urgent need to improve the technological level and quality of communication PCBA.

Hitechpcba's Telecom PCB Assembly Capabilities

In terms of sophisticated networking and telecom solutions, the telecommunications industry is perpetually changing and evolving. Our professional team is aware of this, and as a result, employs a comprehensive array of technology to provide telecom PCB Assembly services to meet the industry's diverse requirements. By continually updating our technologies, processes, and equipment, we endeavor to provide products with enhanced functionality, dependability, and adaptability. By collaborating closely with customers, we ensure they receive the most effective Telecommunications PCB assembly solution in a timely manner.

Hitechpcba can offer from telecom PCB fabrication, electronic components sourcing, telecom PCB assembly, wire harness assembly, functional test to final box build. Armed with the most advanced SMT and through hole assembly lines, and applied with the most strict quality standards and procedures, Hitechpcba has always been providing customers the highest quality products.

Communication technology development:

With the promotion of the information technology revolution and economic globalization, the world telecommunications industry has undergone tremendous changes. The wave of development and change sweeps the globe and becomes an industry with the fastest growth and the greatest market potential. The annual sales of world-class multinational enterprises exceed 20 billion US dollars, and some of them reach 40 billion US dollars or more.

With 5G communication coming to maturity and entering the market, many communication equipments will be eliminated or updated, and the demand for research and development and purchase of 5G equipment will be greatly increased in all walks of life. With the development of 5G, more RF components are needed for the increase of frequency band. The increasing number of RF front-end devices makes the demand for PCB higher.

At the same time, high speed and large capacity become the development trend of the PCB industry. More stringent requirements are put forward for frequency and layer number. The number of high-speed PCB layers of core equipment reaches more than 40 layers, and the industry technology will be further divided into three parts. With refinement and refinement, the requirement for PCBA is higher.

Hitechpcba offers prototype and final telecom pcb assembly in small/bulk volumes for the following applications to meet customer demands.

IP PBX Systems

Satellites

Broadband Equipment

Phone Switching Systems

Waveguide Grating

Fixed and Mobile Networks

Signal Boost Online Systems

Video Conferencing Systems

Signal Amplification

High Speed Routers and Servers

Information Security

Military Communications

Space Communications

Cell Transmission and Tower Electronics

Wireless Industrial and Commercial Phone

Contact Hitechpcba now and find out why thousands of engineers rely on us for their Telecommunication PCB assembly projects.

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese