PCB Box Build Assembly

What is PCB Box Build Assembly?

Boxed builds, also known as system integration, can be anything from simple PCBAs (printed circuit board components) mounted in small enclosures to cabinets housing complex electromechanical systems. Box assembly involves design, production and construction of all links.

Complete assembly includes all other assembly work involved in electromechanical assembly with the exception of the production of printed circuit boards. Box building is sometimes called "system integration."

Boxed means designing and manufacturing enclosures, assembling PCBAs, assembling cable and wiring harness assemblies, and even installing electrical and/or pneumatic systems. Hitechpcba Manufacturing provides a full range of services including packaging, labelling and shipping to your location.

Box build Assembly service and process

Many customers are manufacturers themselves and require not only printed circuit board assembly, but also final assembly of innovative products.

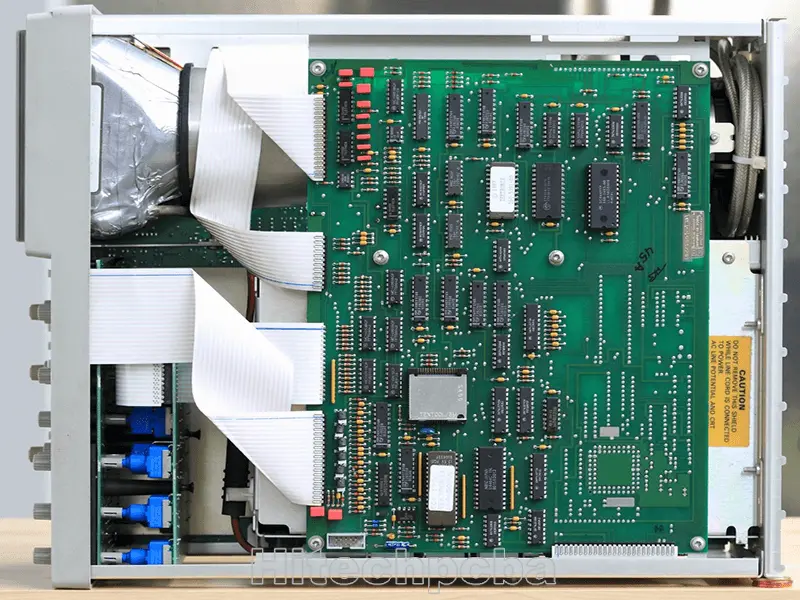

"Box building", also known as system integration, is the complete assembly of a customer's finished product. The process extends beyond the production of printed circuit boards (PCBs) to electromechanical assembly, including enclosure fabrication, installation and routing of cables or harnesses, and installation of subassemblies and assemblies. A box can refer to a PCB assembly (PCBA) in a cabinet full of wires, a small enclosure, or a complex, fully integrated electromechanical system with pneumatics and electronics.

These box build assemblies include the following components:

product assembly

system-level assembly

Product segment assembly

Packaging and Labeling

test

Software loading and product configuration

After-sales service

Warehousing and Traceability

We proudly provide turnkey solutions for all your outsourcing needs. Our final box assembly business has grown to meet the needs of our customers with complete solutions. We can source all the materials needed, build the PCBAs, supply any cables needed and complete the manufacturing process by building the customer's end product.

At Hitech Circuits, we free our clients to focus on other aspects of their business. Our services help companies reduce the need to invest in internal capital and other resources.

Our dedicated box building team can complete assemblies from small and simple to large and complex. Contact us today for a free quote on your next box building job.

What is included in the Box Build component?

Box construction process

The boxed process is specific to each project, and each step can involve varying levels of complexity. For example, one step might involve simply placing a printed circuit board component (PCBA) inside the housing. Subsequent steps may include the complex task of connecting the PCBA to the user interface display.

The most common box assembly processes include the installation of subcomponents, the installation of other components, the wiring or wiring of wiring harnesses, and the manufacture of housing.

6 ways to shorten the Box Build Assembly process

To get good boxed assembly, you must consider certain factors. Be sure to provide this information to your service provider.

The following items are important information provided to Hitech Circuits. The information contained here can shorten the assembly time of the whole machine and provide higher quality electromechanical assembly.

Product size

The dimensions of the device include details about the dimensions and weight of the components. This detail provides with the necessary information to decide how to process the units throughout the assembly process. Storage, shipping, packaging, and shipping are all processes that are affected by dimensional information.

Bill of Materials (BOM)

Bill of Materials is arguably the most important piece of information provided to Hitech Circuits. It is called a recipe, recipe, or ingredient list. BOM helps understand all the key components and materials that need to be purchased and what the customer will provide directly.

Each item on the bill of Materials has a specific purpose, procurement process, and associated costs. The BOM should contain details about the items number, reference mark, part description, quantity, manufacturer name, manufacturer part number, package, part type, etc.

A well-crafted bill of materials can help suppliers anticipate production delays and develop alternative plans for complete machine construction.

3D CAD model

Visualization of the final product is important to the box-building process. 3D CAD (three-dimensional Computer Aided Design) models can provide such visualization. Software packages for 3D CAD design are common among electronics contract manufacturers. These 3D CAD tools can also convert computer drawings into build instructions, thereby shortening the complete assembly process.

Sample unit/prototype

The finished product assembly can be an important physical tool for planning the complete assembly, especially when other sources of information are not available. Hitech can often take a rough prototype from a customer and quickly manufacture multiple equivalent components. A skilled electromechanical assembly team can often replicate a complete box build with minimal documentation in addition to the sample prototype unit provided by the customer.

Test case

The customer should determine which tests need to be performed during the assembly process. Test cases can include visual inspections, factory acceptance tests, and functional specific tests.

Safety is a major consideration for any electrical equipment. The basic test of electrical system includes ground connection test and flash test. Experienced Hitech will provide guidance on the types of tests that should be performed during assembly to optimize production time and provide safe electromechanical components.

Packing and shipping information

Outlining how the final boxed components will be packaged and shipped before the manufacturing process begins can provide important planning information for electronics manufacturers. This detail allows Hitech to determine how to manage these cells throughout the assembly process to optimize assembly speed.

Start assembling

Both complex and simple boxed assembly depend on comprehensive requirements gathering. The more information at hand you have to discuss with the manufacturer during the planning phase, the faster you can produce a higher quality, safer product.

PCBA box assembly service

Box build Assembly is a full process service from PCB manufacturing, parts procurement, PCB SMT, assembly and testing.

Case manufacturing service

Hitech Circuits offers Box build manufacturing services in industrial controllers, consumer electronics, Internet of Things (IoT) modules, electronic and electrical equipment and more. Box build is the assembly and production of PCBAs. The cable and motion motor will be packed into boxes and sent to the dock as a complete set of products.

As an important link of electronic manufacturing, Box Build requires strong process control and quality control ability due to many manual processes. In the process of container construction, relevant management methods such as SOP operation specification, station self-inspection, QC full inspection, on-site sampling of QA and OBA sampling inspection before shipment must be strictly implemented.

At the same time, bar code management system is adopted to effectively trace registration, distinguish good from bad products, and achieve the expected target of assembly pass rate and customer quality random inspection pass rate.

Apply for Box Build Assembly quotes immediately

Box building assembly process

Box assembly is an important aspect of electronics production. Most electronic devices contain boxed components. The use of Box build assembly can never be underestimated. In this article, we discuss what you need to know about PCB boxed assembly.

Your assembly and electromechanical assembly service manufacturing partner.

To complement our printed circuit board assembly (PCBA) business, we offer complete machine assembly and electromechanical assembly services, both partial and full product integration, as well as final assembly for end users. Our partner manufacturing plant combines traceable assembly, testing and packaging, complemented by our electrical and mechanical assembly expertise.

Our technicians are well equipped to handle complex box construction and electromechanical components requiring multiple wiring harnesses and arrangements, welding, pneumatic assembly, specific torque requirements, as well as sealed dust-free environment components with positive air pressure for precision optical sensors or infrared devices.

Customizable box construction and electromechanical components

You will benefit from our world-class final assembly operations in our partner's dedicated manufacturing facility. We are proud to be ISO 9001:2015 certified and are committed to continuously improving our processes and operations in order to consistently deliver quality products to our customers.

• After PCB assembly, we use a variety of automatic wire cutting and stripping machines, universal crimp and cable tester for cable and harness assembly according to your product requirements.

• Our team of integration experts can support electromechanical components for simple, complex or custom box assembly and flexible or rigid flexible components such as PCBs, cables, wiring harnesses, external or internal frames and panels.

• After final assembly, dielectric and functional tests are performed to verify that the final product meets electrical safety requirements and to ensure that it performs as expected.

• Final assembly quality control and assurance is part of our quality management system and includes customized Acceptance Quality Limit (AQL) checks and sampling audit process plans.

• We offer customizable logistics, packaging and shipping solutions, including partial or combined shipping, global shipping options and direct shipping to OEMs or end users.

The testing phase of the manufacturing process that occurs during PCB assembly and boxed assembly.

What is the value of a custom, high-quality boxed assembly?

The advantage of a custom box is that it can be created according to your specific requirements. It can be built to be compatible with all existing systems and is designed to help your system run as smoothly and efficiently as possible.

An "off the shelf" box build will usually suffice for most of your needs, but rarely for all of your process's needs. This can be problematic for the critical business, as anything less than perfect is not good enough, as it may affect profits and margins. By having Hitechpcb Manufacturing create custom box builds created for your business, you don't have to sacrifice functionality and/or compatibility in any way.

Quality assurance

Another advantage of custom boxes is that you can rest assured of quality. Mass-produced products often compromise on the standards of materials used. However, when it comes to custom builds, you have complete control over the quality of your components. This helps ensure that you get the performance, compatibility, and longevity you need. We also fully document and review all of our quality control procedures to help ensure that our customers are satisfied with our service every time. Many of our components are produced in-house, which allows us to further guarantee the quality of our assembly.

Cost value

Hitechpcb Manufacturing not only guarantees quality, but also provides excellent value for money. As a manufacturer of custom wiring harnesses and other components, we don't have to pay inflated prices to other manufacturers. Our purchasing team can source the best materials at low prices and operate efficiently to further reduce costs. This means we can create boxes at competitive prices without having to compromise on quality.

Custom box builds even let you build the shell to your own specifications, helping it fit into its place while also aesthetically to your liking.

PCBA electronic product processing process

1. Customer data file

Customers deliver Gerber files, PCB files, coordinate diagrams, BOM list, PCBA Test Plan and other matters needing attention generated by electronic product design to us.

2. Document review

Convert the contents of data files into internal production standard documents, such as engineering documents, set sheets, etc. It is important to timely discover important issues that have not been clearly marked by customers, such as component direction, PCB process and delivery time of raw materials, and communicate with customers in advance to avoid affecting production and delivery.

3. Technical preparation

According to the PCBA precision, complexity and quality requirements of customers, the PCBA team studied the production plan, the issuing requirements of laser steel mesh, QA inspection standards, with the corresponding vehicle, fixture and other specific content, in order to achieve the PCBA electronic products processing straight through rate.

4. Material purchase and arrival

Based on customer’s BOM list, calculate spare parts and wastage quantity, and purchase corresponding components from original manufacturer or large agent.

5. Material inspection and machine loading

The components will be strictly subjected to IQC (incoming material inspection), and sampled for appearance screen printing, electrical performance and mechanical performance to ensure the production quality of PCBA.

6. Start production

Submit the arrived PCB circuit boards and components to SMT and DIP production lines for pasting and welding production, strictly follow the production process method formulated by PE engineers, and pass IPQC and OQA manufacturer inspection to ensure that the pasting and assembly requirements are met.

7. Testing and delivery

According to the PCBA Test procedures provided by customers, strict PCBA test was carried out, including line on-off, current/voltage value, signal noise, temperature and humidity, etc., and when necessary, help customers to carry out FCT function test and subsequent Burn In Test for the firing process. Ensure that PCBA electronic product processing quality requirements are met and delivered.

PCBA electronic product processing cycle and price

PCBA electronic products will be processed before the proofing process, the proofing process is the same as that in mass production, but because the quantity is very small, between 5-10 pieces, so the proofing price is generally more expensive than mass production. Of course, it is up to the manufacturers to decide whether to close. PCBA proofing depends on the complexity of PCB board and solder joints, the number of materials to calculate the price, generally about 100 USD. PCBA electronic product processing price is calculated by point, the price of different PCB board is different. The proofing cycle of PCBA electronic products is generally about 5 days, and the production and processing cycle is generally about 20 days.

PCBA electronic products processed products display

Why do you choose us to process PCBA electronic products?

(1) 15 years of long-term service to foreign customers (

(2) Project manager, procurement, IQC, IPQC, OQA, PE and other perfect position setting and staffing, full of enthusiasm

(3) Support 0201 SMT pitch precision, maximum 12 layers PCB board, A+ grade material, new and original components, complete PCBA testing equipment

(4) Customer-oriented service philosophy, providing thoughtful technical and after-sales service support

PCBA electronic product processing outsourcing, need from PCBA production capacity, technology, service, experience and other aspects of screening, we have an international concept, Hitech Circuits look forward to working with you to create the market!

What does the average complete PCB box build assembly service include?

Our team will work closely with you to understand exactly what you require. We will also use our experience to advise you and ensure that the finished product is of the highest standard. If you have any questions along the way, such as: "What is a wiring harness?" Please feel free to ask questions.

Our services will include everything from design to development. The unit will be fully built and then rigorously tested to ensure it works as expected when it is delivered. We will also package and tag the build, and ensure that it is safely delivered to your premises.

Why work with Hitechpcb for PCB fabrication and PCBA Manufacturing?

If you are looking for a PCBA manufacturer that can meet all of your PCB box assembly needs, Hitechpcb manufacturing is the one for you. Hitechpcb Manufacturing specializes in custom assembly, which means we will tailor the assembly to your needs. Our experienced and talented team has the expertise to tailor solutions to your needs. Please feel free to contact us for solutions that meet your needs.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

3F, B5 Dong, Zhimeihuizhi, FuYong, Bao’an Dist. Shenzhen, GuangDong, China 518103

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese