Electronic parts sourcing services

Electronic parts sourcing services

Quick quotation for sourcing electronic components

We know that low-cost component sourcing is fundamental to providing our customers with the most competitive possible manufacturing costs. By using our global sourcing team, we are able to obtain the most competitive prices in the global market. Our global supplier network also allows us to track components that would normally be difficult to procure.

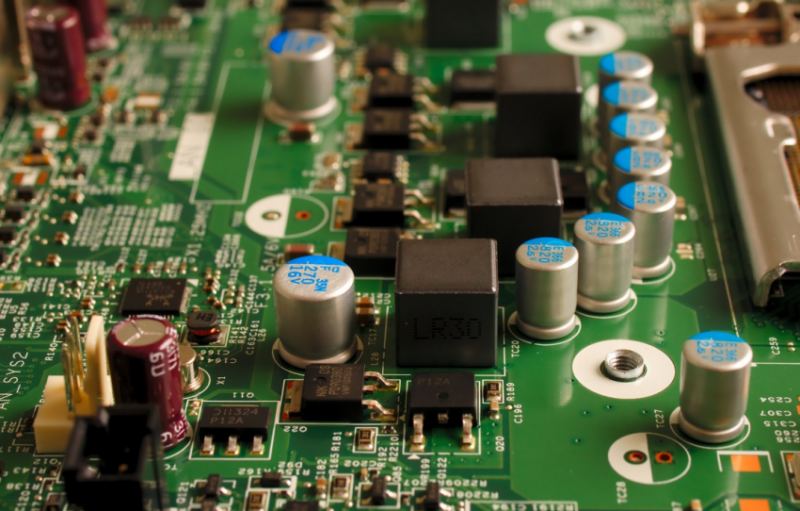

PCB parts procurement

The number of printed circuit board (PCB) parts on the market today is limited. With the increasing demand, component procurement is difficult to complete by oneself. Finding PCB and IC suppliers with quality components can simplify the process and help you meet your business needs.

Hitech Circuits Co., Limited. We are a trusted supplier of PCB manufacturing, Electronic parts sourcing services and PCB assembly. We provide integrated circuit procurement solutions for businesses in the globe world. If you need help finding PCB parts, Hitech Circuits can help.

Starting today!

We can relieve you of the trouble of purchasing parts

Component procurement is the key link of PCB assembly. With our trained team, we can find and supply you with a variety of electronic parts sourcing services, We check the shipping of each component to ensure that your order is of high quality.

Our unique strengths include:

• Authorized Dealers: We purchase all components from certified dealers. We liaise with each supplier to ensure that we supply only the best parts.

• Quality service: Our team will work with you to assess your order requirements and ensure you get the components quickly.

• Cost effective solutions: We source our components from consistent sources and we offer the most competitive possible prices while still providing fast, quality service.

• Certified quality: We follow strict ISO quality guidelines to maintain our ISO registration.

• Hard-to-find components: We have a vetted group of broker contacts who are able to locate the hardest-to-find components.

Hitech Circuits can help you save time and effort in finding electronic parts sourcing. Our process is simple and ensures that you get components when you need them.

We can help purchase common parts

Our team has experience in electronic components assembly and so on, so we understand that quality parts are essential to your operation. That's why we only offer the quality electronic parts:

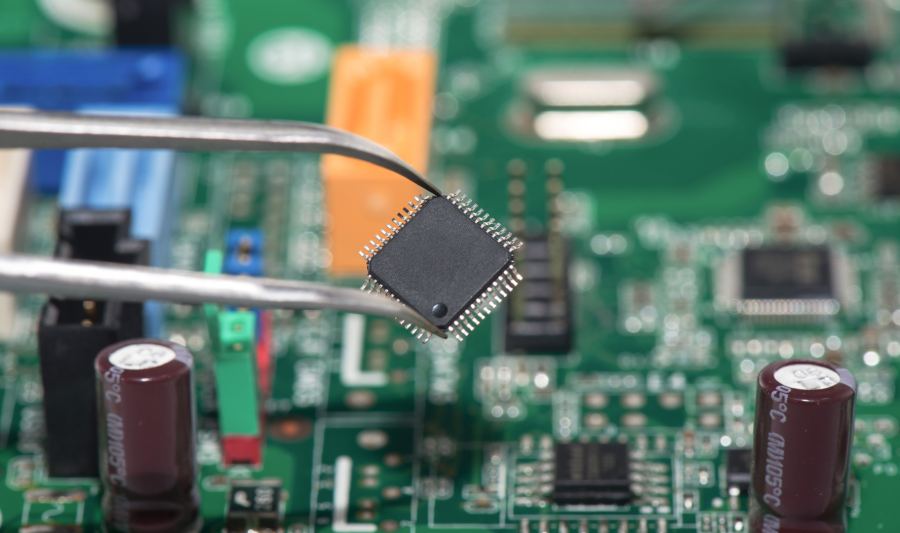

Integrated circuit (IC)

An IC is a small enclosed circuit made of a semiconductor material. In integrated circuits, connections are usually created on silicon crystals. IC units have many practical electronic applications.

We can purchase components such as:

• Capacitor

• Resistor

• Transistor

• Additional metal connections

Contact a Hitech Circuits representative

Printed circuit board assembly

PCBs are made of a range of materials that form layers to transmit data from one location to another. PCBs usually contain more precious, highly conductive metals, such as gold, and each component has a specific cost.

Elements of a PCB include:

• Substrate

• Laminate

• Solder resistance layer

• Silk screen printing

We can provide all these components and more. We also offer PCB assembly services and quality assurance agreements to deliver complete units. For more information about PCBs, check out our page and learn more about their different functions and applications.

We can help – ask for a quote now!

Hitechpcba is a top PCB component supplier, we are committed to simplifying your search for quality parts. We offer small and medium volume products and we have many years of experience in finding, testing and selling quality electronic components.

If you are interested, we can help you find the right parts in the quantity you need. Ask for a quote on our solutions now!

Electronic parts sourcing strategies against constraints

While designing electronic circuit boards offers artistic opportunities, the entire PCBA development process requires adherence to boundaries or constraints. Most of these restrictions are well-founded and necessary. For example, established standards limit the number and type of defects and errors acceptable for manufacturing boards according to IPC performance classifications. However, other restrictions can be temporary and unpredictable.

These limitations affect design choices when selecting components for an ODM or OEM PCBA. Designers must know and understand the constraints in order to develop an electronic component procurement strategy to ensure that boards are manufactured in a timely manner and that operational, performance, and reliability goals are met.

What causes the limitation in purchasing electronic parts?

When developing a circuit board, component selection can determine the downstream success of the entire project. After all, selecting a substandard or forged component can cause the PCBA to fail or be unreliable. In either case, if it results in a redesign and/or recall, your relationship with your customers and your company's reputation will suffer with it, not to mention the impact of lost revenue and additional costs on your bottom line.

To avoid these outcomes, you need to understand the reasons for the constraints that limit the selection of electronic parts, listed below.

Reasons for procurement restrictions on electronic parts :

• Component attribute restrictions

This limitation seems intuitive. However, some component limitations may not be obvious, making acceptable electronic parts unavailable for your design. These include humidity, sensitivity and heat restriction. A thorough understanding of the end product's use cases and requirements will help you best determine the required component properties.

• Obsolete components

The product life cycle of all electronic parts begins and ends with the minimum amount of available inventory. Not knowing the availability of the components used in your design can lead to redesigns and redesigns that reduce your return on development investment. Help ensure product success by selecting components that promise to be available throughout the life of the project.

• Long lead time

Although it may be difficult to determine the amount of time it takes to customize an electronic NPI, there is usually a ceiling on development time before the product is likely to be discontinued or your profitability prospects diminish. One of the main reasons for prolonged development cycles is that your CM has to wait for components. You can work with your CM to determine the risks associated with all the components that may be working in your project.

• Limited suppliers

At the best of times, all electronic parts come from different sources. As the government works to develop regulations to limit the impact of COVID-19, the industry is learning that unforeseen events or circumstances can severely limit procurement options. Choosing off-the-shelf components, or components with off-the-shelf alternatives, can help avoid usability issues.

• Supply chain disruption

Supply chain disruptions, whether due to health pandemics, factory fires or other emergencies, can be catastrophic for industries that rely on unavailable electronic components. For example, some automakers have had to halt production because of reduced production of key semiconductors. To hedge this risk, some manufacturers order extra stocks of key components that they can use throughout the product's life cycle.

As the table above shows, some electronic parts source restrictions are common, while others are unpredictable. Absolute immunity from any procurement issues can be elusive; However, developing a procurement strategy for electronic parts to minimize the impact of procurement restrictions can help ensure a successful product launch.

Optimize your electronic parts purchasing strategy

Often, there is a separation between component selection and procurement. Sourcing and procurement professionals may find themselves at the mercy of design decisions made by electronics engineers who may not consider the market availability of key components. It may be more effective to view component procurement as a supply chain issue, and both the developer and the CM have a role to play in ensuring component procurement is optimized. This is best achieved by following a set of guidelines for purchasing electronic parts.

Guide to effective electronic parts sourcing strategy

• Optimize your component selection process.

The best way to optimize the component selection process is to adopt a risk-reducing electronic parts ourcing strategy. This includes understanding the component lifecycle, avoiding outdated components, and using only reputable vendors.

• CM cooperation with supply chain management services.

CM does not have dedicated supply chain services, or their activities simply reflect the work you do for full consignment component procurement. Therefore, you must make supply chain management QC for your manufacturer.

• Established the supply chain service type.

There are three supply chain service levels, with different responsibilities for you and your CM.

• About Hitech Circuits

1. The whole consignment

Here, you are solely responsible for managing your component supply chain, which can be cost effective if sufficient internal supply chain resources are available. The responsibility for the supply chain falls squarely on the developer.

2. Turn the key

Advantages: This option places the greatest responsibility on the CM that is likely to have a well-established and reliable supplier base. It also frees up internal resources for other development activities. Choosing the wrong CM can be costly in terms of service level, turnaround time, etc. Therefore, an established, established manufacturer should be sought.

3. Partial turnkey

Advantage: With this option, CM can keep an inventory of critical and/or exotic components. You can also leverage CM relationships with reputable vendors. Requires an entrenched CM with reliable sources, and requires some internal supply chain resources.

Following the guidelines outlined above will go a long way towards establishing an effective procurement strategy for electronic components with emergency resilience. Hitech is an industry leader in fast, high-quality prototyping and on-demand PCBA manufacturing, providing dedicated turnkey QC-based supply chain management, including intelligent inventory control, to ensure electronic parts shortages do not disrupt your board building process.

To help you get started on the best path, we provide information for your DFM check and enable you to easily view and download DRC files. If you are an Altium Designer or Cadence Allegro user, you will simply add these files to your PCB design software. For mentor Pads or other design packages, we provide DRC information and Excel.

If you are ready to manufacture your design, please send your Gerber files and BOM files to us. If you would like more information about the purchasing strategy of electronic parts, please contact us.

Hitech's software-driven smart factories provide industry leading custom turnkey PCBA manufacturing services

• Virtual PCBA contract manufacturing.

• Quick and accurate quotes.

• Provide DFM support from day one of design.

• Digital threading with real-time monitoring.

• Fastest turnaround time in the industry, maximizing ROI.

• QC certified agile manufacturing processes support risk management.

• Standard and advanced QC testing.

• Worry-free supply chain continuity.

• Focus on rapid prototyping and small batch production.

• PCBA development optimization for complex critical system industries such as aerospace, medical equipment, automotive and industrial.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

3F, B5 Dong, Zhimeihuizhi, FuYong, Bao’an Dist. Shenzhen, GuangDong, China 518103

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese